Assembly lines often rely on handheld tools and manual part loading. Operators pick fasteners from trays and work one screw at a time. Each pause to load or align a screw slows the cycle. Over long shifts, that lost time adds up. A screw feeder supplies fasteners automatically at the workstation. A cordless impact wrench delivers power and torque without a hose. Together, they transform a manual station into a semi-automated cell. Operators guide the tool and part while the system feeds screws and drives them at high speed. This pairing boosts output, cuts fatigue, and raises quality. Below we explore how screw feeders and cordless impact wrenches work, the benefits of their integration, best practices for setup, and why Flexible Assembly Systems stands out as your partner.

Screw Feeders in Handheld Operations

A screw feeder holds hundreds or thousands of fasteners in a bowl or track. It orients each part and presents it at a pick point. Operators no longer hunt in bins or trays. They pull a trigger and the tool picks the next screw in one smooth motion.

Vibratory feeders use small pulses to move parts up a spiral path. As each screw rides the track, gravity and guide rails orient it upright. At the top, a chute holds the screw ready. Linear feeders vibrate parts along a straight trough. Step feeders lift parts onto staging platforms by rapid up-and-down motion. Each style fits different screw shapes, materials, and line speeds.

In handheld work, a feeder mounts beside the tool stand or on a small cart. A short chute or pick arm places the screw close to the tool muzzle. Sensors detect part presence and empty-bowl conditions. Feeder controls link to the impact wrench so you only drive a screw when one is in place. This coordination prevents missed drives or blank hits.

The Role of Cordless Impact Wrenches

Cordless impact wrenches pack power and portability. A brushless motor and hammer mechanism deliver torque in quick pulses. That pulse action breaks loose tight fasteners and drives screws into hard materials with minimal reaction torque. Operators hold the tool firmly but feel little vibration.

Battery technology now offers long runtimes and fast recharge. High-capacity lithium packs power 200 to 600 Newton meters or more. Smart battery indicators show state of charge. Rapid chargers restore packs in under an hour. Some systems allow hot-swap: drop in a fresh pack without shutting down the station.

Without a hose, the operator gains full freedom of motion. Crews work overhead, around obstacles, or on mobile carts with ease. Tool weight stays low with compact brushless motors. Grips use vibration-damping materials. Multi-torque control settings let users match force to different screw sizes and materials. Some models also log drive counts for traceability.

How the Duo Creates a Smooth Workflow?

Pairing a screw feeder with a cordless impact wrench turns assembly into a one-step cycle. The operator positions the part, pulls the trigger, and the feeder delivers one screw. The impact wrench pulses until it reaches the set torque. A light or tone confirms completion. The operator moves to the next hole without ever touching a loose fastener.

This flow cuts out the hand-motion loop: reach for screw, pick up screw, align screwdriver, drive screw. Each eliminated step saves seconds. Over hundreds of cycles, total cycle time drops by 20 to 40 percent. Operators feel less wrist strain because they handle only one tool, not two actions at once.

Sensors and controls lock out the drive function if no screw is present. This avoids blank hits that force rework. Torque control settings on the impact wrench prevent over-tightening. Some models stop at the exact torque value. Others use a slip-clutch mechanism to hold force within a narrow band.

Key Benefits of Integration

Screw feeders and cordless impact wrenches bring clear gains in speed, quality, and ergonomics. First, cycle times fall. A one-step process replaces multiple hand movements. Second, every joint meets torque spec. Rework rates drop. Third, operator strain eases. They guide the tool rather than load screws. Finally, data capture grows. Cordless tools with counters log fastener counts and torque passes. Feeder sensors log part usage and alerts. You gain a record of output and errors for quality audits.

These gains add up. On a 15-second manual cycle, a 25 percent cut saves nearly four seconds per unit. Over a 10-hour shift, that equals hundreds of extra parts. Low scrap rates free more units without extra material cost. Ergonomic benefits reduce injury risk and absenteeism. Digital logs help meet audit standards and pinpoint process issues.

Best Practices for Setup and Integration

Proper integration makes all the difference. Start by matching feeder capacity to line speed. A feeder that runs out of screws creates a new bottleneck. Choose a feeder bowl or linear trough sized for your screw dimensions and desired parts per minute.

Next, select impact wrenches with the right torque range. Low torque tools suit electronics or plastics. High torque models handle steel fasteners in auto subassembly. Look for quick-set torque ranges and simple user interfaces. Battery voltage and capacity should cover a full shift or allow hot-swap.

Mount the feeder and tool fixture to minimize operator reach. Place the feeder chute so the screw drops naturally into the tool nose. Use a torque arm or retractable balancer for the impact wrench if the tool weight exceeds ergonomic limits. That support removes fatigue from the operator’s wrist and shoulder.

Link sensors on the feeder to the tool control logic. Only allow a drive cycle when a part is present. Add an emergency stop and clear‐jam function. Line controllers can pause the cell if a feeder empties or a tool signals error. This keeps scrap low and prevents time lost on silent failures.

Train operators on the full workflow. Show them how to load screws, change feeder inserts for new screw types, swap and charge batteries, and clear jams safely. Regularly review torque tool calibration and battery health. Schedule feeder cleaning and vibration checks to keep parts flowing smoothly.

Return on Investment and Cost Savings

The investment in a screw feeder and cordless impact wrench outlays more than a manual screwdriver and trays. Yet the return arrives fast. Calculate saved labor hours by measuring cycle time drop. Add less rework from torque errors. Factor fewer tool changes and battery swaps. Include health-related savings from lower ergonomic strain.

A 30-percent cycle time improvement often pays for itself in weeks. Scrap rates can fall by half, saving on parts and labor. Battery hot-swap and fast charging remove downtime on long shifts. Better data capture helps avoid warranty claims and meets quality standards. Across multiple stations, small gains per unit become large gains per day.

Applications and Industry Fit

Many industries benefit from this duo. Electronics assembly uses tiny screws and requires precise torque. A vibratory feeder bowl with a narrow track handles small screws. A low-torque impact wrench drives delicate PCB fasteners without damage. Appliance makers attach brackets and panels with steel fasteners. High-capacity battery packs power through thick sheet metal. Auto parts subassembly often spans multiple torque levels. One station might handle wheel hubs while another secures interior trim. Modular feeder bowls and multi-torque wrenches adapt across stations in minutes.

Medical device makers need traceable torque data and no-jam performance. Cleanroom-rated feeders and sealed impact wrenches keep particles low. Furniture manufacturers gain speed on wood inserts. Battery-powered tools free crews from air hose tangle on the shop floor.

Addressing Common Challenges

Integration challenges often stem from vibration, screw shape, or operator habits. (Vibration – Vibrations from nearby equipment can shake parts off track. Isolate the feeder with rubber mounts or anti-vibration pads.) Screws with odd head shapes or angles may jam in the bowl. Use a custom feed insert or linear feeder trough designed for your part profile. Operators used to hand feeding may tug on the feeder chute. Train them to let the feeder present the part and guide only the tool. When you plan for these issues, you keep downtime to a minimum.

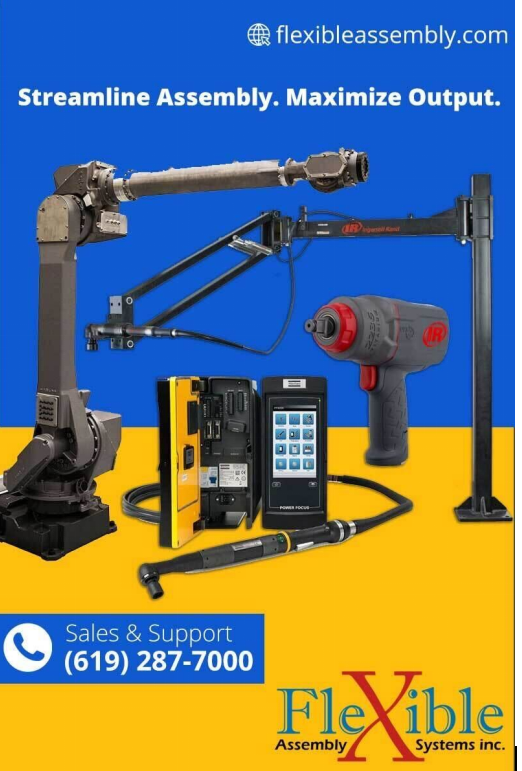

Why Choose Flexible Assembly Systems?

Flexible Assembly Systems brings experience in hands-free stations. We start with your part list, torque specs, and cycle targets. Our engineers recommend the feeder type, bowl size, and track layout. We match impact wrenches by torque range, battery pack, and balancer arm. You receive a turnkey station with wiring diagrams and control logic. On-site our team mounts the feeder, tool fixture, and controller. We test cycle performance and train operators on setup, battery swaps, and jam clearance. We also offer preventive maintenance plans with spare parts kits for inserts, filters, and tool brushes. When you need a fast response, our field service team arrives with parts on hand. With Flexible Assembly Systems as your partner, you avoid integration headaches and keep production moving.

Scaling for Future Growth

As you add new products or shift volume, Flexible Assembly Systems scales with you. We keep feeder modules and tool kits in stock for fast delivery. Changeover between screw types takes minutes with our quick-swap insert kits. Our control software lets you store multiple feed schedules and torque settings. You can load the right profile at the push of a button. For multi-cell plants, we offer centralized data collection. You view output and error rates across all stations from one screen. This visibility helps you spot trends and address issues before they grow.

Conclusion

Optimizing handheld operations with screw feeders and cordless impact wrenches transforms manual stations into high-speed, high-quality cells. You cut cycle time, reduce fatigue, and ensure every joint meets torque specs. The combination of automatic feeding and cordless power drives gains in speed, quality, and data capture. Flexible Assembly Systems offers the tools, integration expertise, and support you need. From site survey to preventive maintenance, we partner to keep your line run